The world is experiencing a critical shortage of battery engineers, but Treetown can help fill the gap. Our team has deep knowledge and extensive experience in designing batteries and their assembly processes.

We specialize in every stage of battery development, from selecting the right cell chemistry and cell, to optimizing battery pack design for performance, longevity, and safety. Our engineers are experts in battery thermal management, ensuring that heat dissipation strategies like liquid cooling, phase-change materials, and active airflow keep cells operating at peak condition.

We also understand the extreme demands of rugged applications, whether it’s designing battery systems to withstand battlefield conditions for military use or ensuring reliable operation in aerospace, marine, or industrial environments. Our work includes ruggedizing enclosures, shock-proofing, and implementing fail-safes for extreme temperatures, vibration, and impact.

Beyond design, we obsess over quality and safety testing. Our team rigorously analyzes battery performance through FEA modeling, real-world stress testing, and compliance with industry standards like UN38.3, IEC 62133, and MIL-STD certifications. We develop advanced Battery Management Systems (BMS) that not only monitor cell health but also optimize charge cycles, prevent thermal runaway, and extend battery life.

Being solution-oriented, we are cell and design-agnostic and select optimal solutions for each application. By leveraging past product design and successes, we can build our experience into greater solutions in battery packs, module engineering, mechanical and electrical design, and ensure our rugged batteries can withstand abusive environments in military applications.

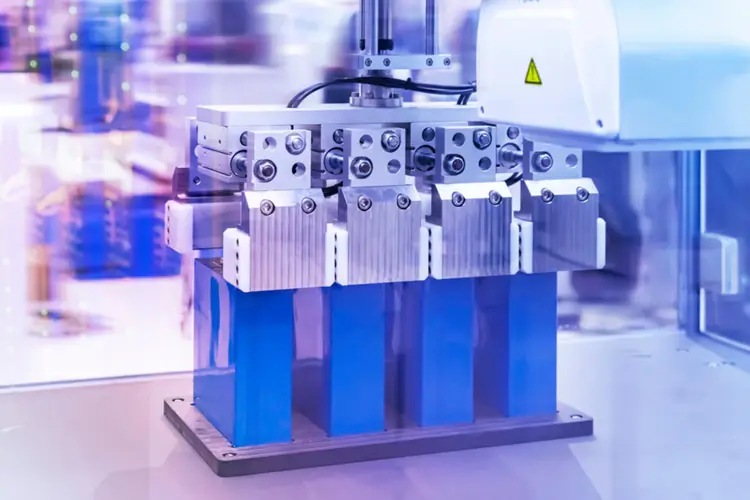

Contemporary batteries feature metallurgically-joined cell interconnections that are resistance welded or laser welded. Do you know what this means? That it's really cool around here, at least we think so.

We can get a lot of mileage out of prototype systems, including:

Our team ensures that the battery pack works as intended via performance and validation testing. Through rigorous validation and analysis for cell selection, battery-scale end-of-line testing, and life testing alongside accurate parameterization for BMS control, you have confidence in production and field use. We are determined to find every problem and challenge before they become costly ones and leverage performance and validation testing and service to achieve just that.

Innovative designs are well and good, but only if they’re practical and they can actually be built in real-life. Our battery-building assets include:

You have the vision. We have the team and expertise to get it built. Let's collaborate to innovate, problem-solve, and de-risk every step of the way.