The 5 Biggest Issues Affecting Li-ion Battery Quality

Li-ion battery quality impacts product reliability, safety, and performance. Learn about the issues impacting quality and our recommendations for resolving them.

Li-ion battery quality impacts product reliability, safety, and performance. Learn about the issues impacting quality and our recommendations for resolving them.

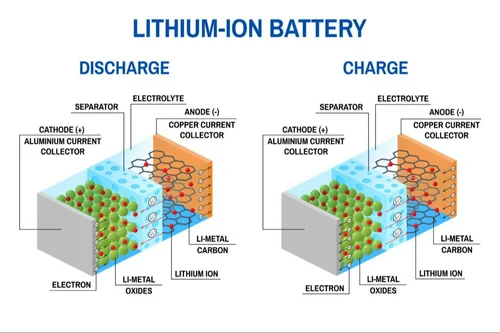

Optimizing battery quality is critical for ensuring reliability, safety, and performance across many applications. Despite significant advancements in battery technology, achieving consistently high-quality lithium-ion batteries remains a complex challenge.

In our experience, these are the five biggest issues when manufacturing these batteries:

Lithium hexafluorophosphate (LiPF₆), the most common salt in liquid electrolytes, reacts with water to form hydrofluoric acid (HF). HF then reacts with lithium in the anode to produce hydrogen gas, which blocks lithium-ion diffusion and causes pouch cells to bloat, reducing effective capacity.

Additionally, HF attacks electrode materials and current collectors, accelerating self-discharge rates, and degrades the Solid Electrolyte Interphase (SEI) layer, increasing internal resistance over time.

Foreign debris on the cathode can oxidize and dissolve in the electrolyte, migrate to the anode during charging, and form dendrites, causing internal short circuits. Particles can also pierce separators or reduce dielectric properties, increasing self-discharge and degrading overall battery performance.

Proper electrode alignment is essential. Cathode overhangs can lead to lithium plating, gas generation, and short circuits due to dendrite formation.

Electrode manufacturing must ensure homogeneous slurry mixing, pinhole-free films, and precise coating alignment. Cell design should favor slightly larger anode plates and ensure anode layers are outermost for manufacturability.

Poor adhesion and cohesion of electrode coatings contribute to increased resistance and decreased cycle life. Incorrect calendering affects porosity and limits ionic transport.

Coat weight must maintain the negative-to-positive ratio to provide sufficient intercalation sites. Improper electrode handling can lead to anode swelling, gas generation, and loss of active material connectivity, reducing capacity.

Robust internal and assembly welds in cells and battery packs reduce faults, voltage loss, increased resistance, reduced cycle life, short circuits, and thermal runaway risks.

Regular destructive and nondestructive testing, including tensile tests, microohm measurements, infrared imaging, and X-ray inspections, ensures weld integrity.

Treetown Tech has helped countless companies develop high-quality batteries for diverse applications. Whether you’re starting from scratch or optimizing existing batteries, we love tackling challenges.

Visit our website to learn more about our battery engineering consulting, prototyping, and design services, or reach out to us today and let us know what project you’re working on.

You have the vision. We have the team and expertise to get it built. Let's collaborate to innovate, problem-solve, and de-risk every step of the way.